Bronte’s Best – large, complex and interesting precision engineered components

#brontesbest

A new social media segment!

If it’s your first time on the Bronte news page i’ll quickly tell you a bit about us. Bronte Precision Engineering is a sub-contract manufacturer with a niche in the machining of large-sized and complex components based in Bradford. Everything we produce is bespoke to our customer needs. By working to technical drawings, CAD Files or existing parts we can provide a complete manufacturing service. Bronte Precision is ISO 9001:2015 approved and has a dedicated Quality Assurance Department which is fully equipped with calibrated gauging and measuring equipment. All of our components are fully inspected before dispatch to ensure that they meet customer specified tolerances. We have maintained full operational capacities throughout 2020 to meet the needs of our customers and we will continue to invest in new machines and staff throughout 2021. If we can be of service to you please contact us by email us at mail@bpel.co.uk or call us on +44 (0) 1274 698 900.

Now, back to the blog…

I’d like to introduce a new social media segment to share with you some of the large, complex and interesting precision engineered components that I will be learning about in my new role as Marketing Manager to showcase the full capabilities of Bronte Precision Engineering. In this segment #brontesbest i’m going to be posting some of the best machined parts I spot on my way round the machine shop on our social media channels. When I say ‘best’ it could be that they’re the most complex to machine part, the biggest part we’re machining or just the most interesting to showcase because of their function. Make sure you’re following all of our channels to stay up to date with not only this segment but all of the latest news from Bronte Precision Engineering.

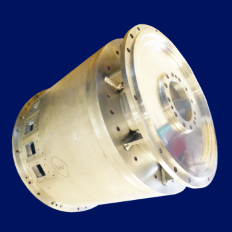

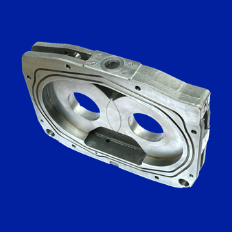

This weeks #brontesbest has been chosen because of the offset hole machined into the component. As you can see the bore has been machined down at a precise angle to join the offset hole. This component is part of a series of similar components we were asked to machine by one of our customers which required both CNC turning and milling. Bronte Precision Engineering has a 8 CNC Turning Machines with a maximum component size of 3000mm long x 805mm Dia and 10 CNC Milling Machines with a maximum component size of 2500mm x 1500mm x 1200mm (with a 800mm rotary table).

I hope you enjoyed this blog and I’ll be writing more detailed case studies on some of our machines parts in future. In the meantime you can connect with Bronte on social media for more content:

LinkedIn – https://www.linkedin.com/company/bronteprecision

Facebook – Bronte Precision Engineering Ltd | Facebook

Instagram – Bronte Precision Engineering (@bronteprecision)

Connect with me on LinkedIn here – Frances Bonny | LinkedIn

If there’s anything else you’d like to see from us or you’re customer or peer who would like to collaborate with us then please send me an email with your ideas at fb@bpel.co.uk.