Gear Cutting

We Keep Your Wheels Turning.

A core service that feeds into many different sectors, Gears are found in nearly every machine. This versatility means that standard sizes for Gears have never been established and as such most require bespoke gears. We produce a wide range of different gears and can also produce Planetary Gear Sets and full Gearboxes. Send across your RFQ today for a no obligation quote and see if Bronte Precision could be your manufacturing partner of choice. mail@bpel.co.uk

Spur Gears: For low-speed applications, Bronte is able to produce a wide variety of Spur Gears. Spur Gears are the most common and are used in applications where noise is not an issue and often at lower speeds. Bronte is able to produce both Internal and External Spur Gears.

Helical Gears: For higher speed applications Bronte is able to produce Helical Gears. Helical Gears differ from Spur Gears in that where Spur Gears have straight teeth, Helical Gears are cut at an angle so as when they mesh the mating flank of the teeth gradually roll into each other which spreads the load during rotation. Bronte is able to produce Internal, External and Double Helical Gears.

Splined Shafts: Complimenting our Gear Cutting service we also provide a wide range of splined shafts, Splines are used as a drive mechanism to transmit torque from one part to another and we are able to produce both internal and external splines.

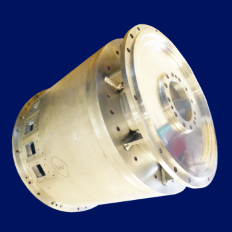

Planetary Gear Systems: As well as individual Gears, Bronte are able to fully manufacture and assemble Planetary Gear Sets. Often called Epicyclic Gears, these sets are able to transmit a high level of torque within a compact space. A central Sun Gear is surrounded by three of four Planet Gears. These are all held together through an outer ring gear with internal teeth. This design spreads the power equally through the gears and enables a Planetary Gear System to achieve a high torque.

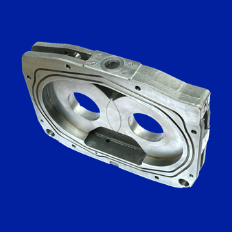

Gear Boxes: Bronte Precision is able to offer full manufacture and assembly of bespoke gearboxes to your drawing. We often produce these for industrial machinery or heavy lifting systems.

For a no obligation quotation, please send through your drawings to mail@bpel.co.uk