Chemical Processing

- Home

- Chemical Processing

Chemical Processing

Ensuring A Positive Reaction

We have extensive experience working on a wide variety of components used within the chemical processing industries and work closely alongside our customers to provide a regular, reliable service of consumables used in production. We work to your technical drawings or from existing components and can reverse engineer components from older models or defunct manufacturers. Bronte Precision is ISO 9001:2015 certified and can provide a complete manufacturing service including sourcing of materials, CNC machining of components and oversight on finishing processes. Common components we have produced include:

Valve Components

Machining of Bodies, Seats, Stems,

Gland Packing, Yokes, Seat Rings,

Valve Plugs, Flanges, Adjusting Rings,

Locating Pins, Eccentric Shafts

Pipeline Components

Mechanical Seals, Gaskets, Weld

Neck Flanges, Slip On Flanges,

Threaded Flanges, Blind Flanges,

Socket Weld Flanges, Seals

Heat Exchangers

Filter Plates, Shoulder Screws,

Bolting Boss, Flanges, Baffles, Mounting

Separation Equipment

Feed Screws, Pistons, Shafts,

Rotors, Housings, Conveyor

Rollers, Support Heads, Return

Idlers, Slewing Rings, Conveyor Components, Mixers

Control Equipment

Manifold Blocks, Stuffing Boxes,

Impellors, Ventilation Housing,

Vacuum Chambers

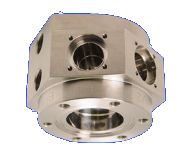

Valve Components

Bronte Precision have a lot of experience in producing valve components for challenging conditions and are able to manufacture in a wide chemically neutral materials such as Nylon to super hard alloys such as Inconel and Monel.

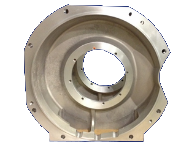

Pipeline Equipment

Bronte have machined pipe itself in the past, but most often we will produce large diameter flanges, fittings and gaskets in stainless steels. We can produce Neck, Slip-On, Blind, and Socket Flanges up to 805mm in diameter.

Heat Exchangers

Bronte often work alongside fabricators in the production of bespoke heat exchangers, this could be the machining and EDM Wire erosion of filter plates to the machining of large-sized fixtures and mounting parts.

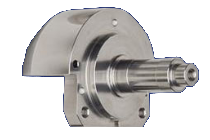

Separation Equipment

We have produced a wide range of components used in the separation of chemicals, gases and raw materials. Everything from Feed Screws and Housing through to the rotating components such as rollers, pulleys and shafts.

Control Equipment

Alongside the valve components we make, Bronte is also able to produce manifold blocks, stuffing blocks and ventilation housings.