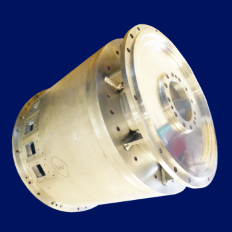

The ’Edge’ by FaroArm® is an industry leading mobile smart measurement tool and has been branded ‘The World’s Most Innovative Measurement Arm’.

What is a smart measurement arm?

A smart measurement arm offers dimensional analysis and is used in the engineering industry to measure components manufactured on CNC machines. It can measure to near perfection using laser trackers and the flexible arms allows the user to cover every mm of the part during inspected. Measurement points are tracked as the arm moves over the surface of the component making shapes traditionally difficult to measure, simple.

Key Features of the Faro Arm Edge

- Improved reliability and capability (compared to traditional measurement tools)

- Mobile which enables it to measure very large complex parts in an location

- Reduced user fatigues means more parts can be inspected per day

- Can be used with CAD software or independently

What does Bronte us the Faro Arm for?

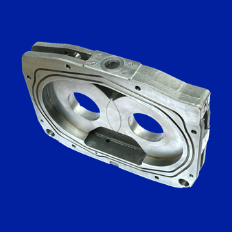

Bronte Precision works to customer technical drawings and quality requirements. The Faro Arm is used for in process and final inspection before components are dispatched as part of our overall quality procedures.

Bronte Precision can also use the Faro Arm for reverse engineering. The Faro Arm can scan the surface of a customer part to create an extremely detailed CAD drawing which is then used to assist with the manufacturing process. Bronte Precision have reverse engineered many parts for the classic car industry and we’ll be dedicating a blog to classic car parts in the near future.

Bronte’s business wide investments

Over the past 10 years, including throughout the pandemic, Bronte precision have invested in several areas of the business. New machines, staff and a 5S system to name a few. These investments have enabled us to offer more large and complex precision machining capabilities to our customers. We have more exciting things on the horizon in 2021 so watch this space!

In conclusion, the Faro Arm has enhanced the quality inspection process at Bronte Precision offering time and expense savings throughout the engineering process. The Faro Arm Edge can be used on small to very large components and ensures that they are all produced to the same standard and same dimensions every time.

If you have any requirements for large, complex or reverse engineered parts please contact us

either by email at mail@bpel.co.uk or call us on +44 (0) 1274 698 900.