News

National Apprenticeship Week 2023

Last week was National Apprenticeship Week, the aim of which was to raise awareness and promote the benefits of apprenticeships. James, Bronte’s Technical Manager, Jane our Engineering Training Mentor and Jack our 4th-year apprentice all attended an Appris Management Limited

Bronte Precision’s Latest Investment – Automated Tool Dispenser

Bronte Precisions latest investments are a Matrix Maxi and Tool Port – Automated tool dispensers. One thing we are working hard to cut down on here at Bronte is lost time, lost time looking for tooling to complete our customers’

Large Gears Manufactured For Low Volume Requirements

Gear Cutting Gears are found in almost every machine. Bronte Precision offers a core service that feeds into many different sectors. Due to the versatility of gears, it means that standard sizes for Gears have never been established and as

Stainless Steel Precision Nozzle Manufacture

What is a Nozzle? A nozzle is a component designed to control the direction or characteristics of flow. They are used to increase velocity as the fluid exits (or enters) an enclosed chamber or pipe. Nozzles are often attached to

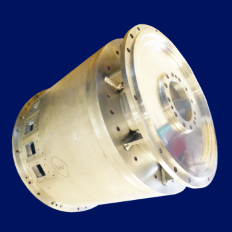

Bespoke Hydraulic Cylinder components manufactured in the UK

Trusted OEM Suppliers Bronte Precision is well placed to manufacture bespoke components for both old and new machinery and often work closely with OEMs as part of their supply chain. Where OEMs are looking for long lasting and high precision

Custom Spline Gear Manufacturing

Complementing our Gear Cutting service we also provide a wide range of splined shafts. We manufacture custom splines to exact specifications. Through our many years of experience, we have the knowledge and expertise to produce external and internal spline gears

Low volume Test Drive Shaft requirement

What is a Drive Shaft? A drive shaft is a component for transmitting mechanical power and torque and rotation, usually used to connect other components of a drivetrain that cannot be connected directly because of distance or the need to

How we manufacture Gear Segment Parts

In this blog we’ll take a look at a part manufactured with a segment gear including all operational steps it underwent. CNC Turning > Gear Cutting > Gear Grinding > Milling > Plating > Inspection Manufacturing the Gear Segment Part

What was our most popular engineering blog of 2021?

Bespoke Rack and Pinion Gearsets Manufactured About the Blog The blog featured a large, recently manufactured Rack and Pinion Gearset. The large rack and pinion were required for a rotary actuator application. A rack and pinion actuator offers greater torque

Custom manufactured Stainless Steel Flanged Shaft

Bronte Precision engineer bespoke shafts and step shafts for a wide range of demanding industrial applications. Our CNC Turning capabilities means we can produce large bespoke shafts and hollow bored shafts. Working from your drawing we are able to accommodate

Bronte Precision Engineering Year Review 2021

It’s been a fantastic year for Bronte Precision and we wanted to celebrate that by sharing this years highlights with you. Here’s to another great year!

Precision Engineered Thin-walled Titanium Tube

In this blog we’ll look at a recently machined Titanium Tube with a thin wall thickness. Titanium and its alloys are being increasingly used in aerospace and biomedical applications due to it’s unique range of properties. However, machining titanium also

Reverse Engineering a snapped Shaft and worn Gears

An entire machine rendered inoperable due to one small broken shaft. Bronte offered a reverse engineering solution to help get the machine back up and running. As you can see from image that the shaft has been twisted inside the

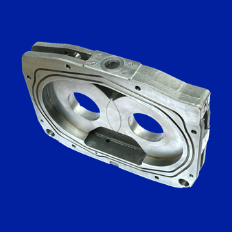

Machining all sides of a Stainless Steel Junction Box

In this week’s blog we’ll take a look at a large junction box for a hydraulic application. The hydraulic junction box reports to a complex manifold, covering a control gear inside it. It’s 660mm x 285mm in size and has

Machining Inconel Superalloys

Inconel 625 Inconel alloys are oxidation and corrosion resistant materials well suited for service in extreme environments subjected to high mechanical loads. Along with its resistance to chloride-ion stress corrosion cracking this material is an excellent choice for sea water