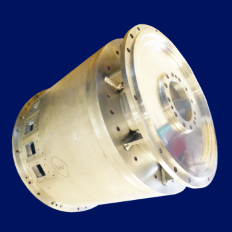

Bronte Precisions latest investments

are a Matrix Maxi and Tool Port – Automated tool dispensers.

One

thing we are working hard to cut down on here at Bronte is lost time, lost time

looking for tooling to complete our customers’ orders. With a few taps of a

screen our engineers can access the tooling they need instantly.

The dispensers have minimum quantity limits set depending on the item and will automatically send an order to our tooling supplier for restocking once the minimum has been reached. This is helping to reduce the time machines spend standing when compared to ordering tooling manually.

The unique software that is installed on the machines will help with a more accurate way of quoting orders. Each time one of our engineers requires a tool, they must input a job number which is linked to our customer’s order. We will then be able to look back and have a clearer idea of what tooling is required if it were to become a repeat order.

These are some of the points that will benefit both Bronte and our Customers

- Drive Down Costs

- Guarantee Production Output

- Optimize Stock Levels

- Streamline Purchasing

- Control Cost Per Unit (CPU)

- Select the Right Tools for Each Job

Send through your enquiries

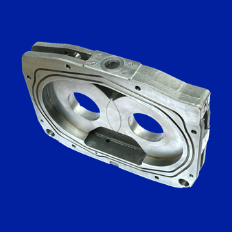

Bronte Precision is an ISO 9001:2015 certified company which is committed to investing in its machinery, processes, and people. The team based at Bronte has a vast number of years experience in various procedures including:

- CNC Milling

- CNC Turning

- Grinding

- Gear Cutting

Now that you have learnt more about our precision engineering capabilities, you may be interested in contacting us for a quotation. Click here.