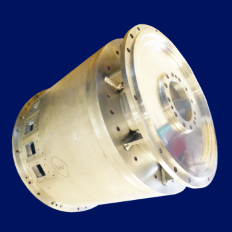

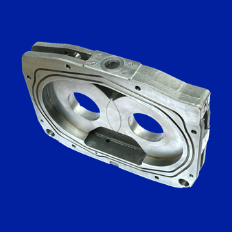

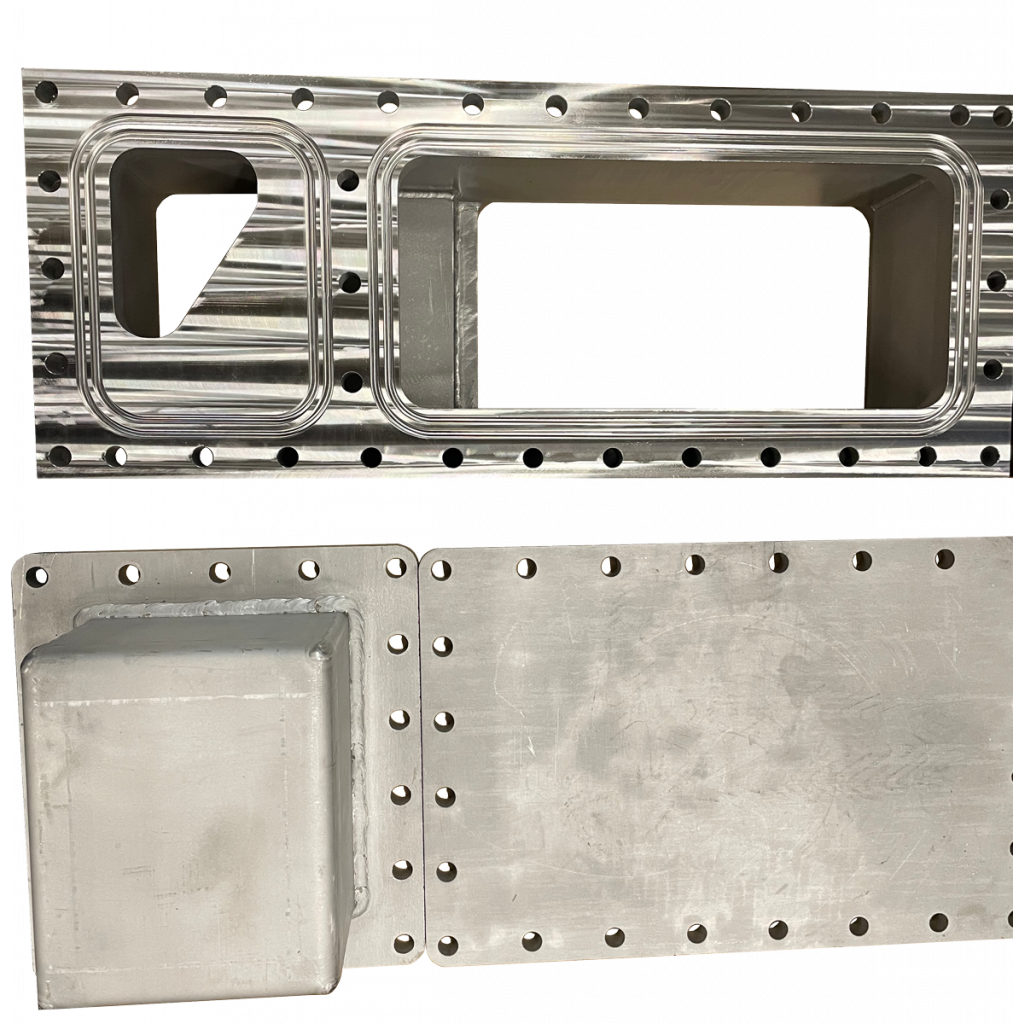

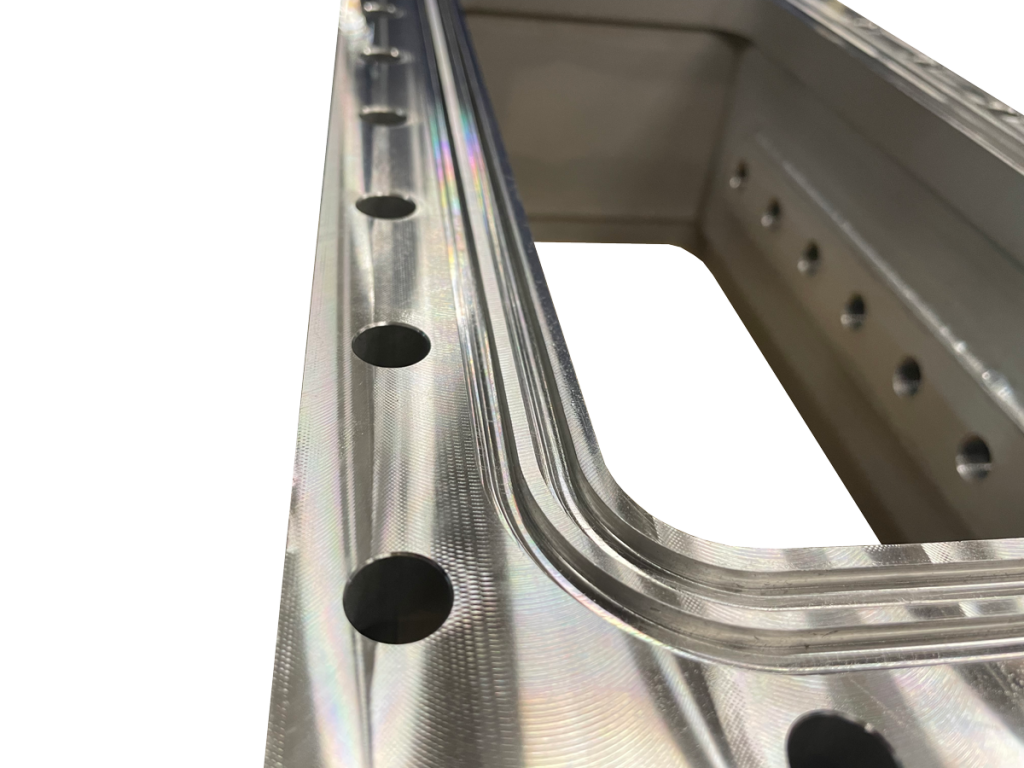

In this week’s blog we’ll take a look at a large junction box for a hydraulic application. The hydraulic junction box reports to a complex manifold, covering a control gear inside it. It’s 660mm x 285mm in size and has been CNC machined on two of our Hass machines. Our maximum machining capacity is 2500mm x 1500mm x 1200mm with 4th axis

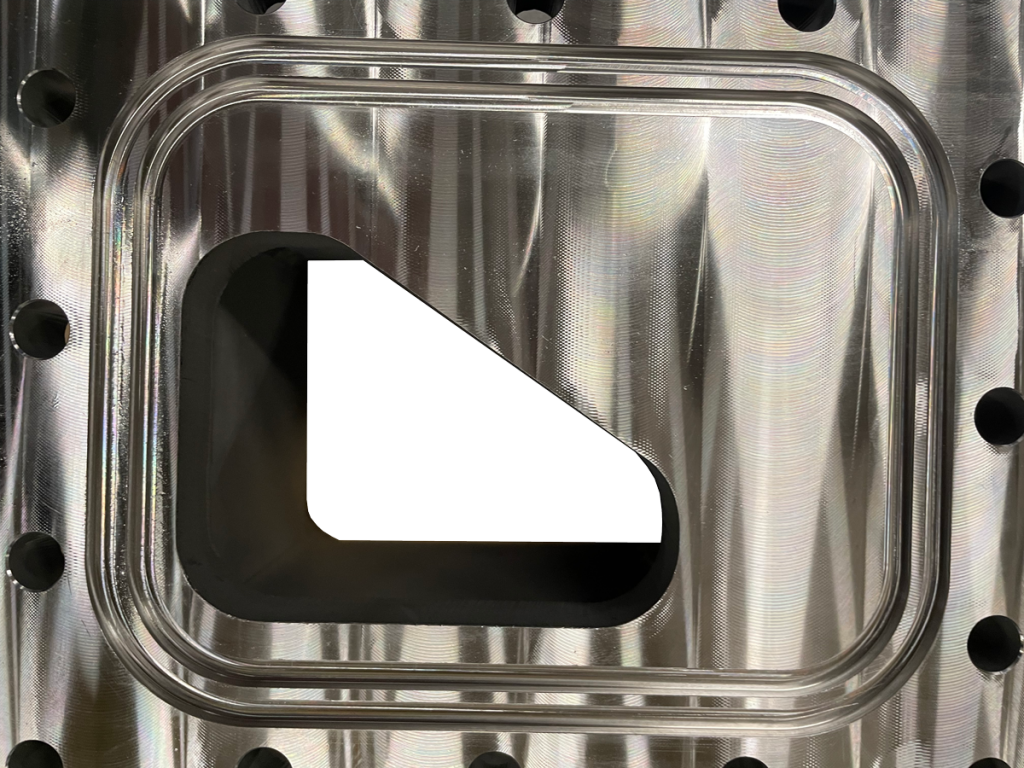

Firstly, it was machined on our VM4 Haas machining centre where we’ve skimmed the top and bottom face ready for further machining. One side was then milled with a complex pattern to tight tolerances where a large o-ring will sit. Finally, the part was then moved onto the VM3 Haas machining centre where we’ve then drilled holes on each side. This large hydraulic junction box is made from 316 stainless steel which is one of the more difficult stainless steels to machine but has many useful properties.

Benefits of using 316 Stainless Steel:

- – Excellent corrosion resistance (wider range of chemicals than 304)

- – Performs well when exposed to relatively high and sub-zero temperatures

- – Suited to all standard methods of welding

- – Ease of cleaning

- – Good heat resistance – oxidation resistance in intermittent use up to 870°c and continuous use up to 925°c, however continuous use at 425-860°c is not recommended for lower grades. In this instance, 316L is recommended.

Bronte Precision have experience machining superalloys such as Inconel (read the blog here) and other exotic materials so stainless steel was no problem at all. We can provide complete manufacturing services where we would also manage the sourcing and procurement of these materials as well. Then the manufacture of components and the application of any specialist finishing processes on behalf of our customers. The ability to provide such a solution means that we can supply a service tailored to the specific needs of each customer.

Request a Quote

Bronte Precision provide CNC milling across a wide range of sectors, materials and components and are proud to be ISO certified with our own in house inspection facilities. You can view our full list of CNC Machining Centres here.

Contact us here to send through your enquiry.