Inconel 625

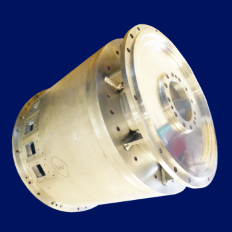

Inconel alloys are oxidation and corrosion resistant materials well suited for service in extreme environments subjected to high mechanical loads. Along with its resistance to chloride-ion stress corrosion cracking this material is an excellent choice for sea water applications. Inconel is also a popular choice for Aerospace applications not just because of its high tensile strength but because it also has outstanding fatigue and thermal-fatigue strength, oxidation resistance and excellent weldability. It can be used for aircraft ducting systems, engine exhaust systems, thrust-reverser systems, and heat-exchanger tubing.

Thread Milling Inconel

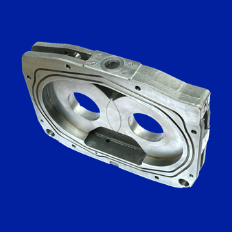

While Inconel’s strength and resistance to high temperatures make it the ideal choice for use in extreme environments, it also poses major challenges for those machining it.

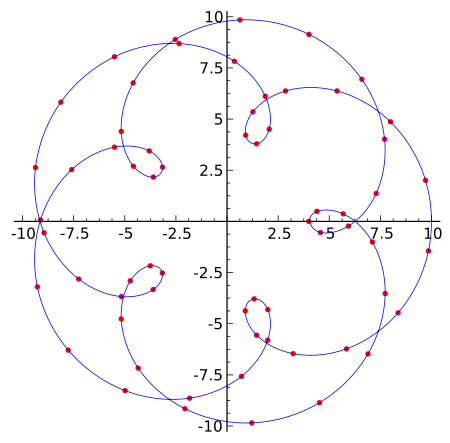

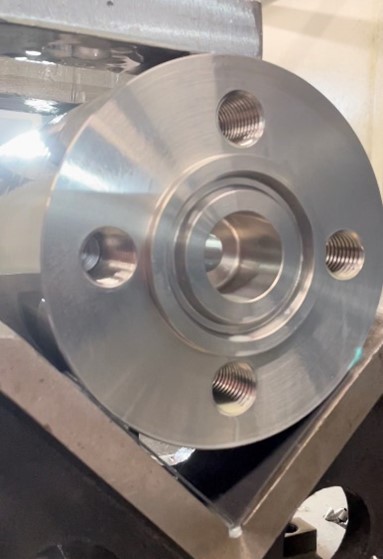

Thread milling is a metalworking process where threads are cut at different sizes through the helical interpolation movement of a rotating tool. The thread pitch is created by the lateral movement in one revolution. Different from tapping, thread milling is primarily applied to large workpieces but in this instance has been used due to the properties of Inconel 625.

Tooling can only last for so long when used on materials as tough as Inconel. Even the toughest tooling will wear down over time from the surface hardness of Inconel. When Inconel is work-hardened, tooling can wear out as heat and pressure builds so regular inspection is crucial. Through spindle coolant is used to improve finish and tool life.

Thread milling also produces a high thread quality. The result of the thread is a higher quality of surface finish, tolerance, angle, etc. compared with other threading methods. When thread milling you will also get a complete thread profile to the bottom of the hole, unlike tapping. Thread milling is the best choice for adding threads to Inconel 625 parts.

Machining Superalloys

Inconel 625 is part of the superalloy’s family. Superalloys are difficult to machine materials due to their toughness, high heat resistance, high operating temperatures, hardness, strength to weight ratio, chemical properties, low thermal conductivity and creep resistance. Bronte Precision’s engineers have experience in producing many types of difficult to machine materials.

Request a Quote

If you’d like a superalloy quotation or anything else including: CNC Turning, CNC Milling, Grinding or Gear Cutting – .Contact us here