What is a Drive Shaft?

A drive shaft is a component for transmitting mechanical power and torque and rotation, usually used to connect other components of a drivetrain that cannot be connected directly because of distance or the need to allow for relative movement between them.

As torque carriers, drive shafts are subject to torsion and shear stress, equivalent to the difference between the input torque and the load. They must therefore be strong enough to bear the stress, while avoiding too much additional weight as that would in turn increase their inertia. Learn more about the material we used for this part further in the blog.

To allow for variations in the alignment and distance between the driving and driven components, drive shafts frequently incorporate one or more universal joints, jaw couplings, or rag joints, and sometimes a splined joint or prismatic joint.

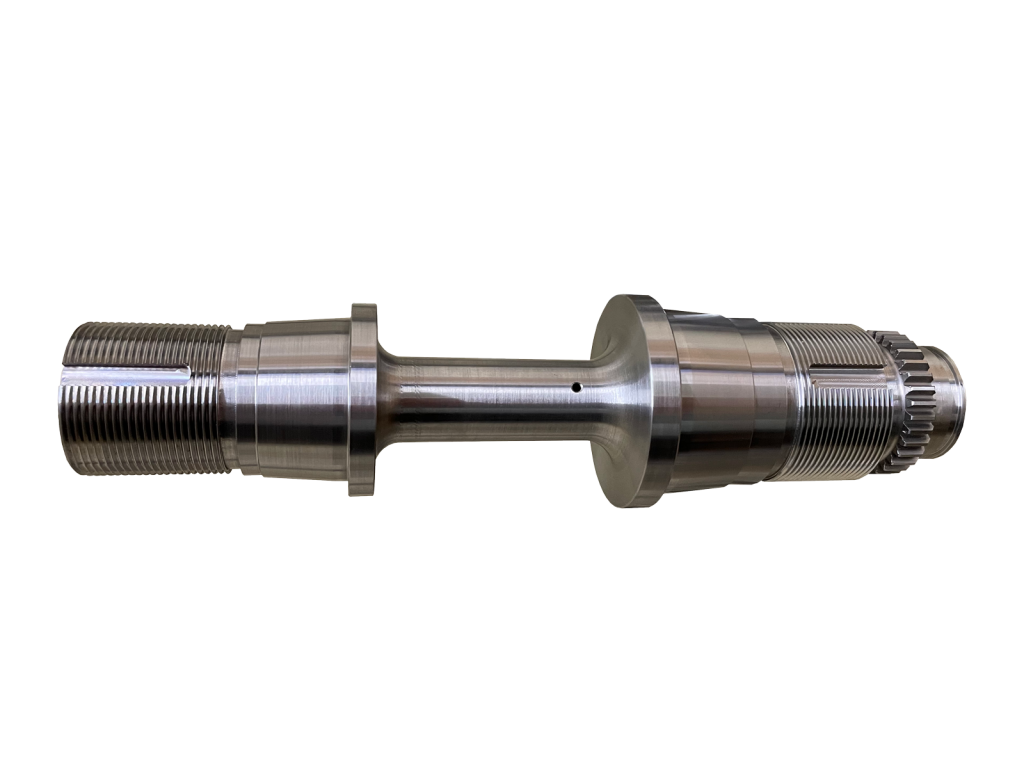

Drive Shaft Part Features

One end of the shaft features an internal spline and the other end of the shaft features an external spline. Read more about Bronte’s Gear capabilities here.

CNC Turning – First the shaft was turned to create to create the shape of the body.

Gear Cutting – Splines were added to both ends of the part.

Gear Grinding – The gear grinding operation is a final finishing process that removes any small deviation on a gear tooth.

CNC Milling – Finally keyways were added to both sides of the part and a small hole was drilled through the center.

Drive Shaft Material Choice

This Drive Shaft is made from EN24T. The steel is a high tensile alloy steel renown for its wear resistance properties and also where high strength properties are required. EN24T is used in components subject to high stress and with a large cross section. This can include aircraft, automotive and general engineering applications for example propeller or gear shafts, connecting rods, aircraft landing gear components.

Request a Quote

Only 1 Test Drive shaft was manufactured. Bronte Precision specializes in low volume complex precision parts, if you’d like a quotation on prototypes or low volume parts please contact us with your requirements. Either as one off requirements or recurring orders.