Gear Cutting

Gears are found in almost every machine. Bronte Precision offers a core service that feeds into many different sectors. Due to the versatility of gears, it means that standard sizes for Gears have never been established and as such most require bespoke gears. Bronte can produce a wide range of different gears and can also produce Planetary Gear Sets and full Gearboxes.

Large Gear Cutting

Bronte Precision are well positioned to offer cost-effective low-volume gear cutting services whether large or small in size. But where some companies are unable to offer larger gear cutting services, we can cut external spur and helical gears up to 1450mm diameter. For a full list of maximum diameters across our gear cutting services click here.

We are currently working on a large one-off gear requirement. This gear is 680mm, 24 tooth and 27 pitch and manufactured using EN8 steel. EN8 can be heat treated to provide a good surface hardness and is a popular choice for general engineering components as it’s much more cost-effective compared to steel alloys.

Complete Gear Cutting

Bronte Precision is able to supply complete components by overseeing the sourcing, machining and finishing. This makes the production of your part quicker, simpler and gives us greater oversight on quality.

Bronte Precision can source your required material from one of our trusted suppliers. We have long-standing relationships which enable us to source materials quickly at cheaper prices. Additionally, we can provide full traceability and certificates of conformity where required.

We have a number of gear-cutting machines capable of manufacturing internal, external, spur, helical gears and splined shafts. After we have manufactured your component, additional finishing processes may be required. We work with a very select group of local suppliers, who are all regularly quality audited enabling us to professional finish the products we manufacture including gear grinding.

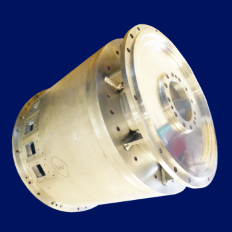

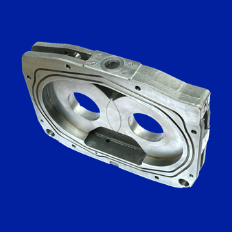

In several cases alongside the full production of individual components, Bronte Precision will also mechanically assemble it into a larger system. We have experience in providing sub-assembly for full Transmissions, Gearboxes, Extruder Heads and Link Assemblies. This can save your company significant time and resources.

During an inspection, we use a CMM directly linked to our CADCAM system which enables us to quickly inspect and produce reports whilst inspecting parts throughout their lifecycle. All inspection equipment is externally calibrated by independent specialists to ensure equipment accuracy.

With your component fully assembled, Bronte will then arrange a courier delivery. We have worked with businesses across the UK and Europe and appreciate the importance of getting your parts to you on time.

Request a Quote

If you would like to discuss any gear requirements you may have, please contact us by email at mail@bpel.co.uk or call us on +44 (0) 1274 698 900.

If you enjoyed this blog, don’t forget to follow us on social media to receive blog notifications, #brontesbest images and videos and all other Bronte news updates.