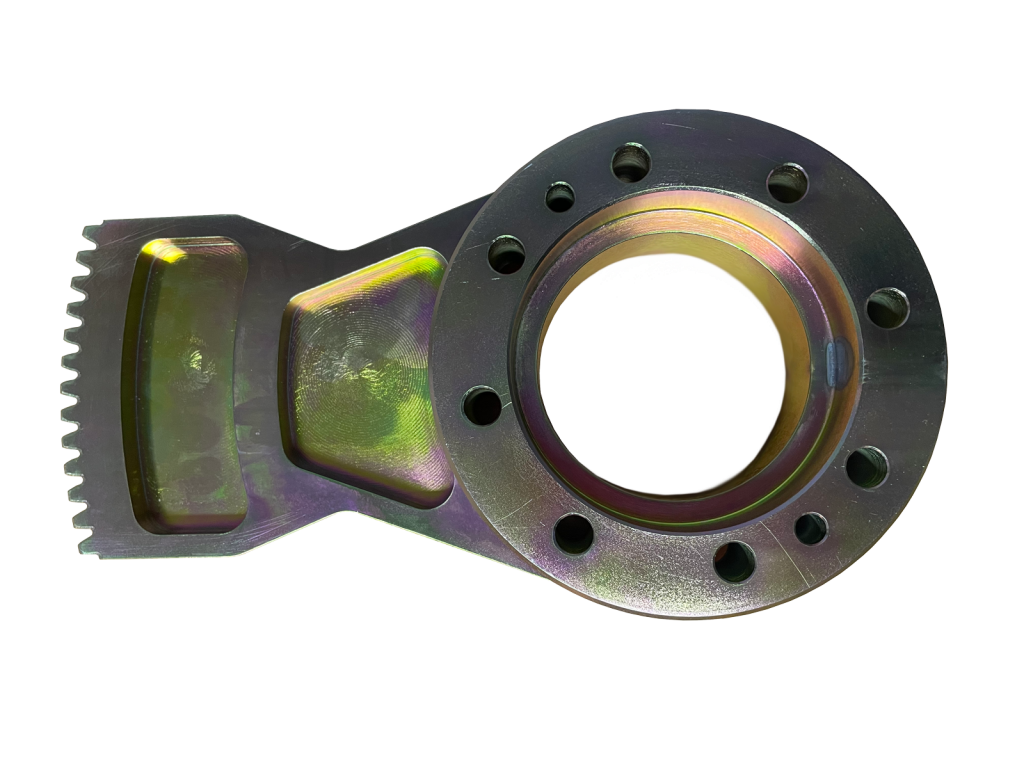

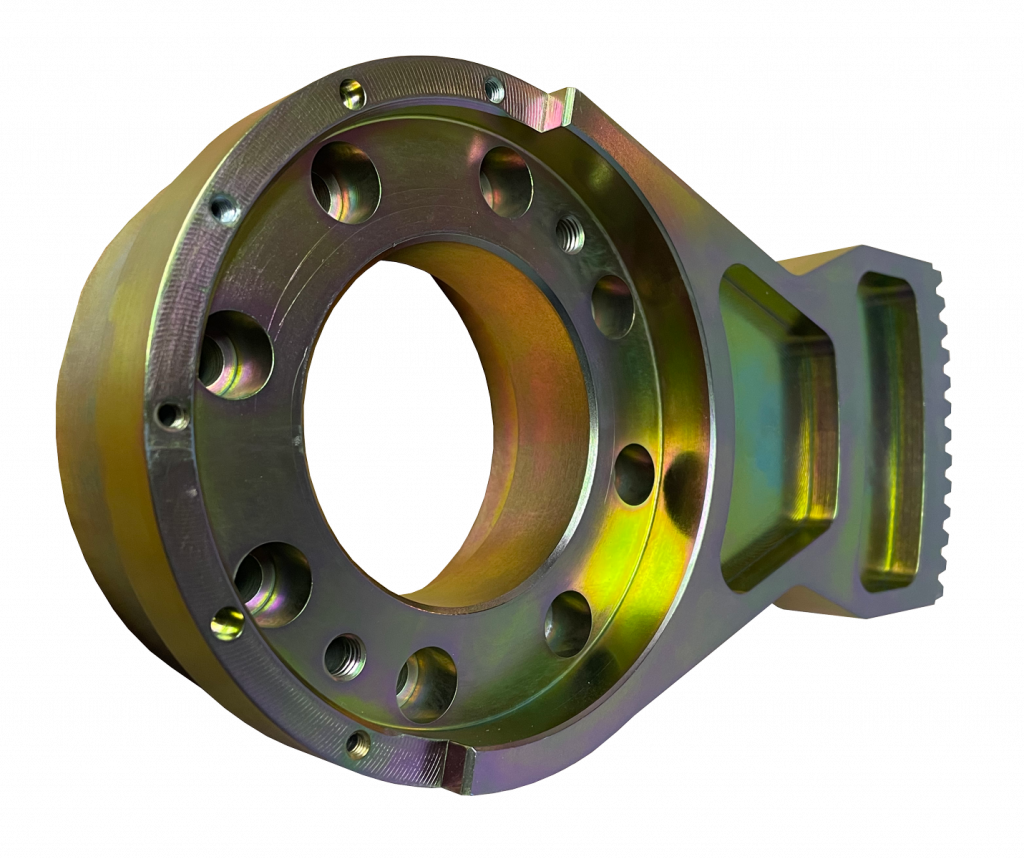

In this blog we’ll take a look at a part manufactured with a segment gear including all operational steps it underwent.

CNC Turning > Gear Cutting > Gear Grinding > Milling > Plating > Inspection

Manufacturing the Gear Segment Part

First of all, we turned the material to 426mm diameter. At Bronte we have 8 CNC Turning machines and can accommodate parts up to 3m in length. Once Turning was complete we then moved onto Gear Cutting. This part required an external spur gear which our engineers have vast experience in producing. We can produce a wide range of different gears as well as Planetary Gear Sets and full Gearboxes. Then the gear undergoes grinding to finish.

The shape of the part is milled on 1 of our 12 CNC machining centers. We have invested heavily in 4th axis computer controlled milling machines which enables us to work on parts with intricate geometries and tight tolerances. We can accommodate a wide range of components up to 2.5m x 1.5m x 1.2m in size on our CNC milling machines and are the most cost-effective in small to medium production volumes. Features such as grooves, chamfers, holes on this part are added as separate operations during the CNC milling process.

Parts are inspected during manufacture and before they are plated. We have long standing relationships with all of our suppliers and can manage the whole process from material sourcing to delivery making it easier for our customers. Our customer requested Zinc Plate and Yellow Passivate for this part which we could offer from our trusted supplier.

As an ISO 9001:2015 company we have standard operating procedures that ensure the same precision and quality in all of our parts. Before dispatch we use our inhouse inspection facilities to check all dimensions are within tolerance, we have many inspection tools including a Faro Arm Edge.

Once the part has been successfully inspected and checked it’s ready for dispatch. We can arrange delivery or collection of components and have our own forklifts available for transporting larger orders. The part went through CNC Turning, Gear Cutting, Gear Grinding, Milling, Plating and Inspection before it was ready for use and demonstrated the complete engineering services Bronte Precision offer.

Request a Quote

Whether you’re an OEM or end user, no matter the industry, we can help you with precision engineered component requirements.

If you’d like a Gear quotation or anything else including: CNC Turning, CNC Milling, Grinding or Gear Cutting – Contact us here.