Bronte Precision Engineering are able to produce Internal, External and Double Helical Gears. One of the specialist double helical gears that we manufacture are herringbone gears. Precision herringbone gears are more difficult to manufacture than equivalent spur or helical gears and are typically used in heavy machinery.

What is a Herringbone Gear?

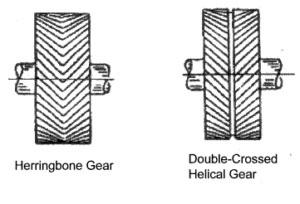

A herringbone gear is a specific type of double helical gear. This specialist type of gear has a side to side (not face to face) combination of two helical gears of opposite hands. From the top, each helical groove of this gear looks like the letter V, and many together form a herringbone pattern. The name comes from the resemblance of the bones of a herring fish.

Like helical gears, they have the advantage of transferring power smoothly, because more than two teeth will be in mesh at any moment in time. Their advantage over (single) helical gears is that the side-thrust of one half is balanced by that of the other half. This means that herringbone gears can be used in torque gearboxes without requiring a substantial thrust bearing. Because of this, herringbone gears were an important step in the introduction of the steam turbine to marine propulsion. Unlike helical gears, herringbone gears do not produce an additional axial load.

The axial loads produced by (single) helical gears can be countered by using double helical or herringbone gears. These arrangements have the appearance of two helical gears with opposite hands mounted back-to-back, although in reality they are machined from the same gear. The difference between the two designs is that double helical gears have a undercut or groove in the middle, between the teeth, whereas herringbone gears do not. This arrangement cancels out the axial forces on each set of teeth, so larger helix angles can be used. It also eliminates the need for thrust bearings.

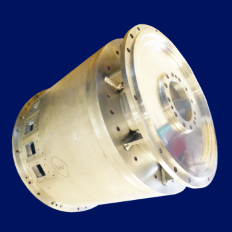

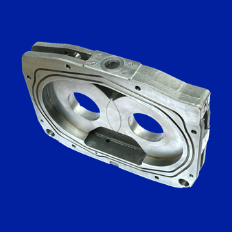

Herringbone Gears manufactured by Bronte Precision

These particular double helical / herringbone gears are also made from exotic materials.

A, has been manufactured using Inconel which is a registered trademark of Special Metals Corporation for a family of austenitic nickel-chromium-based superalloys.

Inconel is often encountered in extreme environments. It is common in gas turbine blades, seals, and combustors, as well as turbocharger rotors and seals, electric submersible well pump motor shafts, high temperature fasteners, chemical processing and pressure vessels, heat exchanger tubing, steam generators and core components in nuclear pressurized water reactors.

B, has been manufactured using Stainless Steel. Stainless steel is a group of iron-based alloys that contain a minimum of approximately 11% chromium, a composition that prevents the iron from rusting and also provides heat-resistant properties then enables it to be used in a number of applications.

Both of these gears have been machined from a solid billet and have a straight bore. We can manufacture with other mounting options such as keyways depending on your application requirements.

If you’d like to discuss any gear requirements with us please contact us either by email at mail@bpel.co.uk or call us on +44 (0) 1274 698 900.