Through the upload of 2D or 3D CAD drawings supplied to us, we can use the software to run a number of simulations on a 3D model of the component before proceeding with live machining.

These simulations can be used to:

- Determine the best tools for the job

- Calculate the optimum toolpath in order to extend the lifetime of the tooling

- Estimate the time it will take to run a particular cutting sequence or machine a component complete from a blank piece of material.

The new investment will be utilised by Bronte alongside its current systems to further streamline its machining processes. This will be achieved by speeding up the programming of complex operations, reducing cycle times and limiting potential errors.

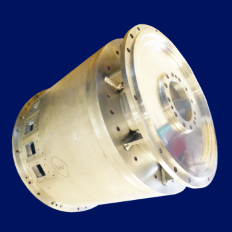

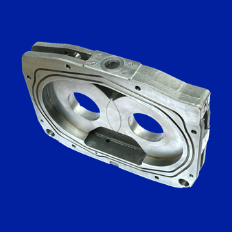

Bronte Precision currently has 8 CNC lathes (Max capacity: 3000mm long x 805 dia) and 10 CNC milling machines (Max capacity: 2.5m x 1.5m x 1.2m) on site at its Bradford facility. If you have any requirements for CNC machining work, contact Bronte Precision on 01274 698 900 or email mail@bpel.co.uk with your RFQ.