Offering a complete engineering service saves our customers time and money whilst ensuring high quality finished components.

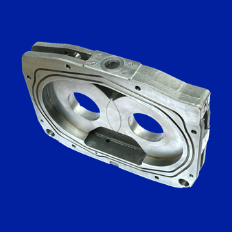

Bronte Precision are sub-contract manufacturers with a niche in the machining of large sized and complex components. Everything we produce is bespoke to our customers needs and we work to technical drawings, CAD Files or existing parts to provide a complete engineering service. We oversee the sourcing, machining and finishing which means the production of your part is quicker, simpler and gives us greater oversight on quality.

We have a team of experienced engineers with specialist knowledge in complicated machined parts that often require multiple process steps, tight tolerances or intricate geometries. We have a number of Multi-Axis CNC Milling and Turning machines including a large CME machine enabling us to take on a wide spectrum of components across different industries.

We work with and can source nearly all material types including: Stainless Steel, Aluminium, Inconel, Monel, Cast Irons, Nylon and many more. We also have long-standing relationships with our suppliers which enables us to source materials cheaper and faster than you might be able to yourself. Traceability and certificates of conformity supplied on request.

After sourcing materials and manufacturing the part, additional finishing processes may be required. This could be Heat Treatment, Electro-Plating, Conversion Coating or Painting. We work with a very select group of local suppliers, who are all regularly quality audited enabling us to professionally finish the products we manufacture.

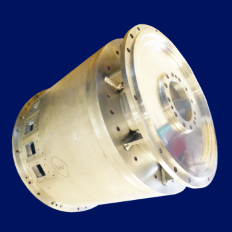

In a number of cases alongside the full production of individual components, Bronte Precision will also mechanically assemble it into a larger system. In the past, we have provided sub-assembly for full Transmissions, Gearboxes, Extruder Heads and Link Assemblies. This can save a company significant time and resource.