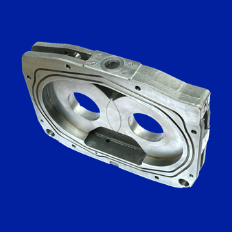

Bronte Precisions latest investment is a VM-3 Hass machining centre. Watch our other machining centre investement from earlier this year here. This now take’s the total CNC Milling machines up to 12 and you can view Bronte’s full list of capabilities here. This is the second new machine Bronte has acquired this year and shows the businesses commitment to developing it’s engineering offerings. As a sub-contract manufacturer, that primarily specialises in the production of large and complex components in small to medium quantities, this machine will increase capacity. That means satisfying more customer requirements.

About our new Hass VM-3 machining centre

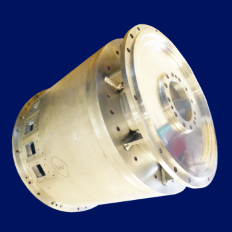

The Haas VM Series machines are high-performance VMCs that provide the accuracy, rigidity, and thermal stability for high-precision industries. Each machine features a generous work cube, a multi-fixturing table, and a 12,000-rpm inline direct-drive spindle. Standard features include the Haas high-speed control with full look-ahead, a side-mount tool changer, a programmable coolant nozzle, an automatic air gun, and much more. Just like Bronte’s last Haas purchase, they have chosen to add Renishaw inspection probes to the machine as well for fast, accurate measurement even during manufacture. Watch the video here.

- Inline direct-drive spindle

- Side-mount tool changer

- Multi-fixturing table

- High-speed machining software

High Speed Machining is a machining methodology that focuses on extremely fast but light, low pressure cuts. The result is an overall increase in the material removal rate. This in turn increases capacity by reducing cycle times.

Send through your enquiries

Bronte Precision is an ISO 9001:2015 certified company which is committed to investing in its machinery, processes and people. The team based at Bronte has a vast number of years experience in various procedures including:

- CNC Milling

- CNC Turning

- Grinding

- Gear Cutting

Now that you’ve learnt more about our precision engineering capabilities you may be interested in contacting us for a quotation. Click here.

Your part(s) may even be produced on our new machine!