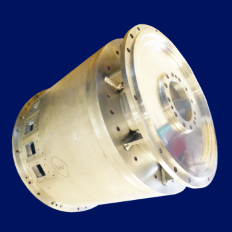

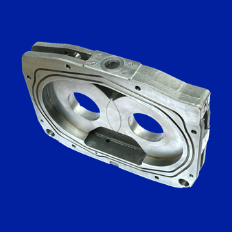

CNC Milling to tight tolerances

In this blog we’re going to look at adding a detailed groove to a Formed Aluminium Extrusion, on one of our new CNC machining centers. As experienced precision engineers, our customers trusted us to get the detail just right.

The groove itself is only 2mm with a chamfered edge and the pattern intricately weaves around this complex shape. It’s centered on wall thickness all along the path and in the video below you can see how we use in process machine probes to ensure tolerances. The groove has been added to each end of the component and it inspected again using the latest faro arm edge technology before dispatch.

Watch our machining process (view in full screen)

Request a Quote

Whether you’re an OEM or end user, no matter the industry, we can help you with precision engineered component requirements. We often work from technical drawings or CAD files and also have the ability to reverse engineer from sample parts if required.

Bronte Precision is an ISO 9001:2015 certified company with vast number of year’s experience in various procedures including:

CNC Milling

CNC Turning

Grinding

Gear Cutting

If you would like to contact us for a quotation. Click here.