Long Shaft Engineering

Long thin shafts are often used for various drive shafts and mixer shafts. Bronte Precision Engineering have many years’ experience engineering complex shafts across different industries. Replacement parts are one of Bronte’s specialties so if a shaft wears or breaks in your machine then Bronte can work with photographs, original parts and CAD drawings to engineer a solution.

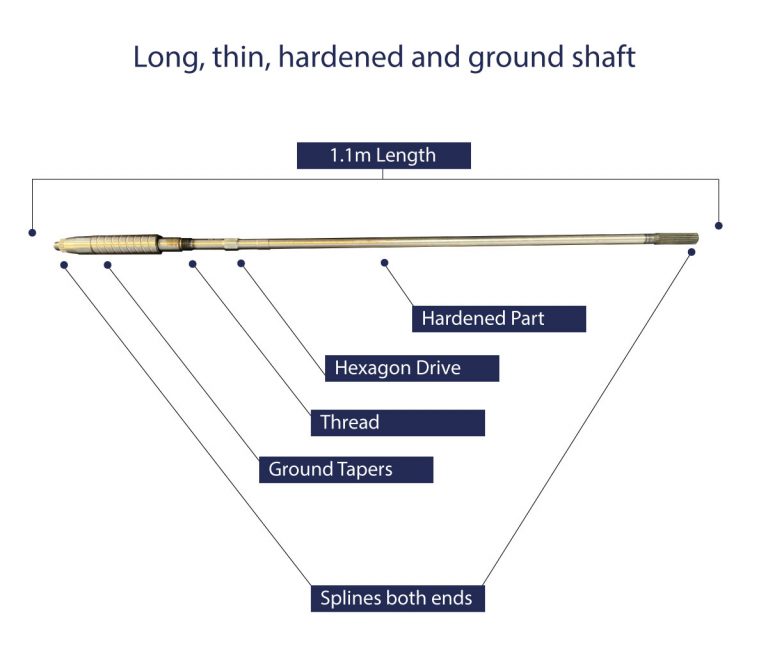

Here’s an example of a power transmission shaft engineered by Bronte. This long, thin shaft has been hardened and ground to meet customers’ requirements. Take a look at some of the shaft features:

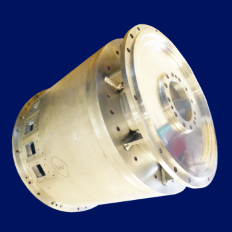

Alpha 1550XS CNC combination

lathe

How does Bronte Precision engineer long shafts? The Alpha 1550XS CNC combination lathe enables us to offer long shaft CNC turning. It has a swing over bed of 554mm, spindle speeds upto 2000rpm and a spindle bore of 104mm. With up to 3m between centres, this is a big lathe with generous machining capacity and size. No other lathes on the market today, including full CNC machines can compete with the XS range for speed of production when it comes to “one-offs” and small batch turned parts.

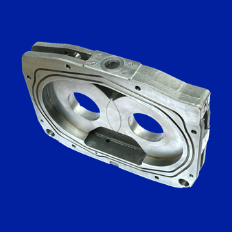

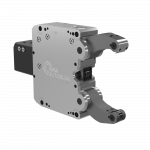

Hydraulic Traveling Steady

Rest

Bronte’s self centering, hydraulic traveling steady rest ensures precision engineering across the length of the shaft. This is because once the steady has been installed into the Alpha CNC Lathe it then moves with machining to keep the aera that’s being turned steady. Without this control, particularly on thin shafts, it’s possible for machining vibrations to interfere with parts and move the offset, resulting in incorrect parts.

The hydraulic traveling steady is just one of Bronte’s investments to continue to offer leading precision engineering capabilities. You can read more about Bronte’s advanced quality inspection here.

For large, complex shaft or reverse engineered part requirements please contact us

either by email at mail@bpel.co.uk or call us on +44 (0) 1274 698 900.