Phosphor Bronze is one of the world’s oldest metal alloys, dating back almost 4,000 years.

The material is well known for its strength, durability, low coefficient of friction and its fine grain. The Phosphorus acts as a de-oxidant, reduces viscosity and therefore improves fluidity, while increasing stiffness and wear resistance.

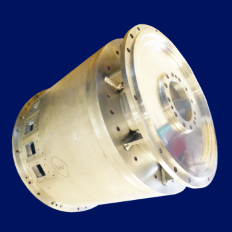

Bespoke Bronze Bush

Bronte Precision have recently machined a small batch of Phosphor Bronze Bushes.

As a sub-contract manufacturer, we primarily specialise in the production of large and complex components which are required in small to medium quantities. We have long standing relationships with our material suppliers and have experience in machining exotic and hard materials. Solid Bronze bushes are used in many applications.

Phosphor Bronze Industry Applications

It is used in a broad range of applications and industries, from aerospace, electronics and chemical to mechanical and marine engineering. Its innate properties make it suitable for products and situations where resistance to wear, fatigue and even chemical corrosion is needed.

For this reason, Phosphor Bronze is used for bolts, bearings, fasteners and other products which need to be designed to withstand fatigue and high stress, while exhibiting high elasticity. The alloy is also highly common in marine based application and very popular in the cryogenics industry. Due to its high electrical conductivity and low thermal conductivity, it can function efficiently as an electrical connection, even in extremely low temperatures. This is valuable, because the material does not need additional heat to function as an electrical component in cryogenic environments. Phosphor Bronze is also used in the storage of spent nuclear fuel, due to its high corrosion resistance.

Phosphor Bronze Components Supplied

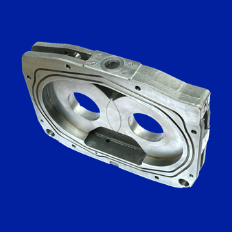

Whether you’re an OEM or end user, no matter the industry, we can help you with Phosphor Bronze component requirements. We often work from technical drawings or CAD files and also have the ability to reverse engineer from sample parts if required.

Bronte Precision is an ISO 9001:2015 certified company with vast number of year’s experience in various procedures including:

CNC Milling

CNC Turning

Grinding

Gear Cutting

If you would like to contact us for a quotation. Click here.